Massive Aircraft Brakes

Taumel's long experience with industry's very varied requirements means that they have the skills to design and build specialized solutions for difficult and demanding assembly projects.

In this case, the manufacturer needed to assemble the massive carbon disk brakes which are used in commercial aircraft.

A Taumel pedestal T-501F was custom-built with an extended machine table to handle these extra-large workpieces.

The T-501F was fitted with Close-up Protrusion Sensing Controls which can sense and confirm that parts are present; and can measure and monitor stud height; protrusion; and the actual forming pressure that is being applied to form the steel studs without harming the carbon disk.

Delicate Precision

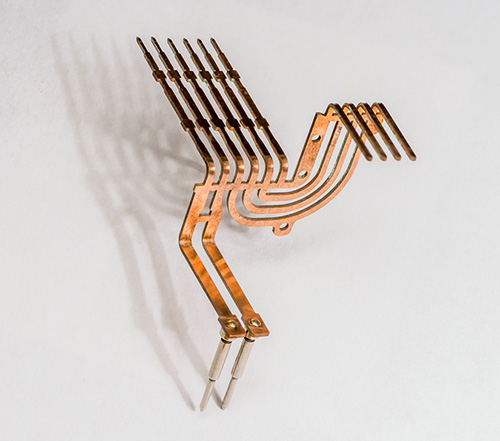

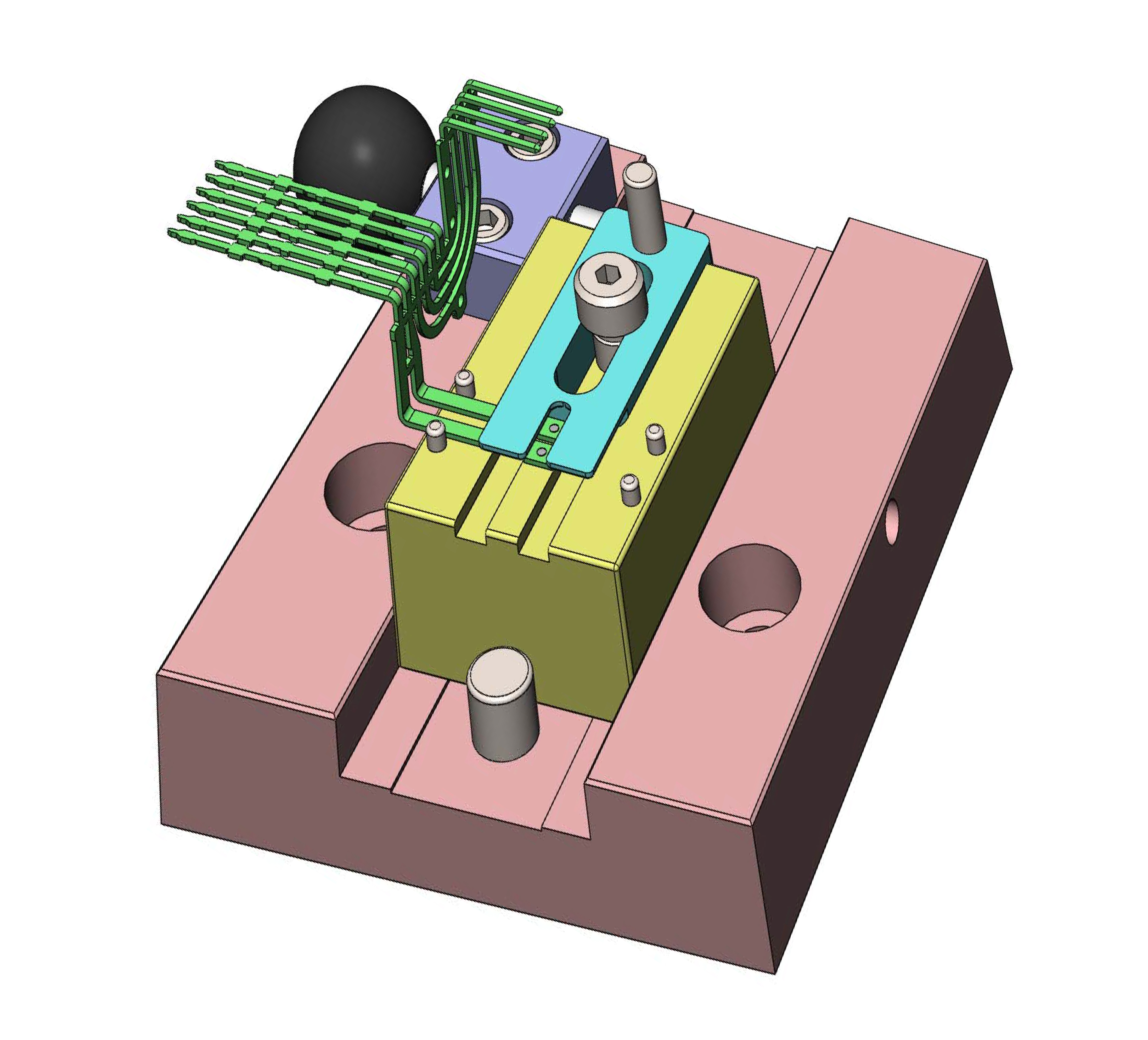

A manufacturer of electronic parts was faced with a very difficult assembly application: the attachment of two minute pins to fragile stamped copper connectors of exceptionally delicate design.

This custom Fixture and Slider were designed especially to handle these delicate parts.

The tiny pins and the delicate stamped contact fingers are carefully protected and accurately positioned during the Orbital Forming process.

Magnetic Core

The manufacturer of these automotive speakers was faced with a difficult assembly application.

The stamped speaker baskets themselves were of rather delicate construction but needed to be fitted with a securely-fastened magnetic core.

They had originally attempted to crimp the magnetic core lip with a hydraulic press.

Unfortunately, the amount of down-force required to form the lip expanded the magnet and introduced radial expansion forces to the speaker basket thus creating unacceptable assemblies and a high rate of rejections.

Taumel suggested that their Orbital process would use only a fraction of the press's operational force and could form the magnet lip gently and incrementally.

A special orbital forming tool, with a protruding end sized to fit the magnet's casing, closed the rim smoothly and safely over the magnet's core without deformation.

This approach eliminated both the deformation and the high rate of rejection.

Taumel's Orbital Forming has the advantage that it accomplishes tasks by using much less forming pressure than a conventional press.

Hermetically-sealed Liquid Meters

Taumel suggested that the manufacturer should use the Orbital Forming process instead because it requires a fraction of the force, compared with a traditional Press operation.

Taumel's Orbital Forming process forms the material smoothly and incrementally by line contact, rather than with the single massive thrust from a press.

Because of the incremental nature of Orbital Forming, the process can be finely regulated and controlled by varying

the pressure, time, stroke depth and speed.

The relationship between these standard adjustments, can provide precise, but infinitely adjustable, control.